New shower wall module: full of technology, free of water

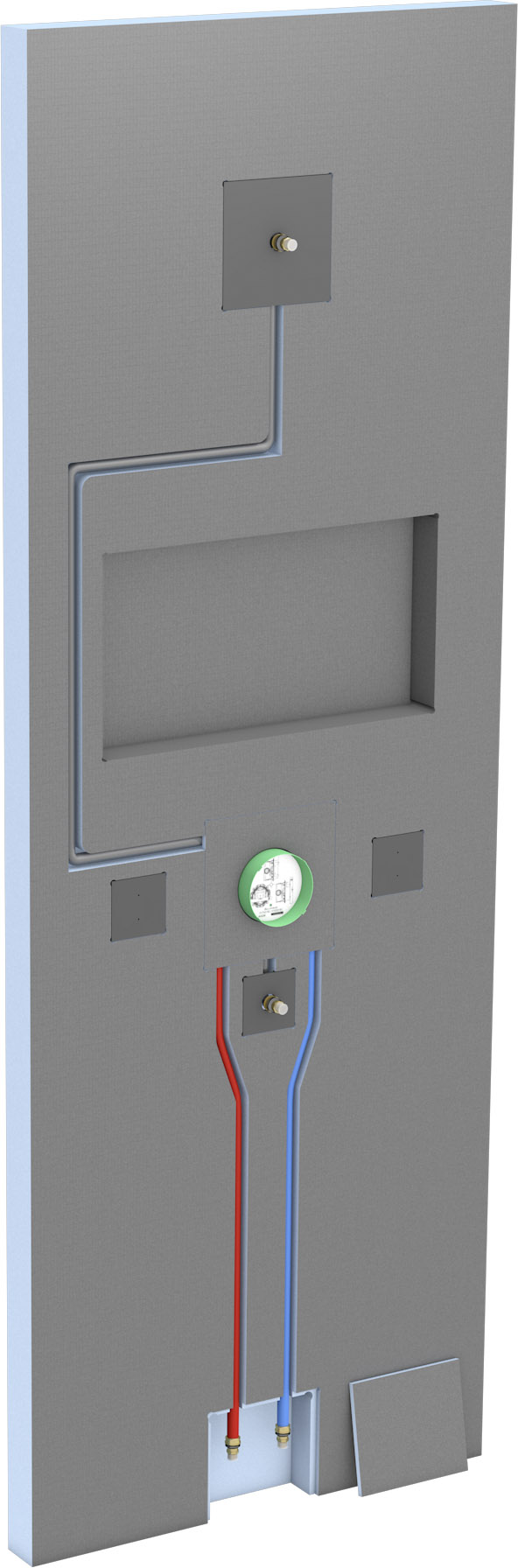

Always at the forefront of innovation, wedi brings a new, ready-to-install shower wall solution to the market that - with its factory-integrated, hot and cold-water pipes, Hansgrohe iBox and reinforcements for the shower outlets - cuts back on labour and interactions between different trades on the construction site. It is not only 100% waterproof, but also saves a great amount of time and hence allows for a faster and safer project completion.

Construction site schedules are usually tight and recently, staff numbers are becoming lower and lower. Undoubtedly, there is an increasing demand for prefabricated solutions that are easy to install and minimise stress through reducing risky installation steps. "wedi products are modular in design and characterised by the ease of their installation. The new Sanwell shower wall module takes this a step further: it combines the work steps of several different trades within one product and, as a result, the installation time is noticeably reduced" says Sebastian Hinze, product manager at wedi. "In addition, the system, including the integrated technology, is tested for water tightness in the wedi factory before dispatch. Besides the time, this prefabricated solution also saves waste on the construction site as well as, due to the reduction of interfaces between different trades, achieves the highest level of system security.“

Faster than traditional installations

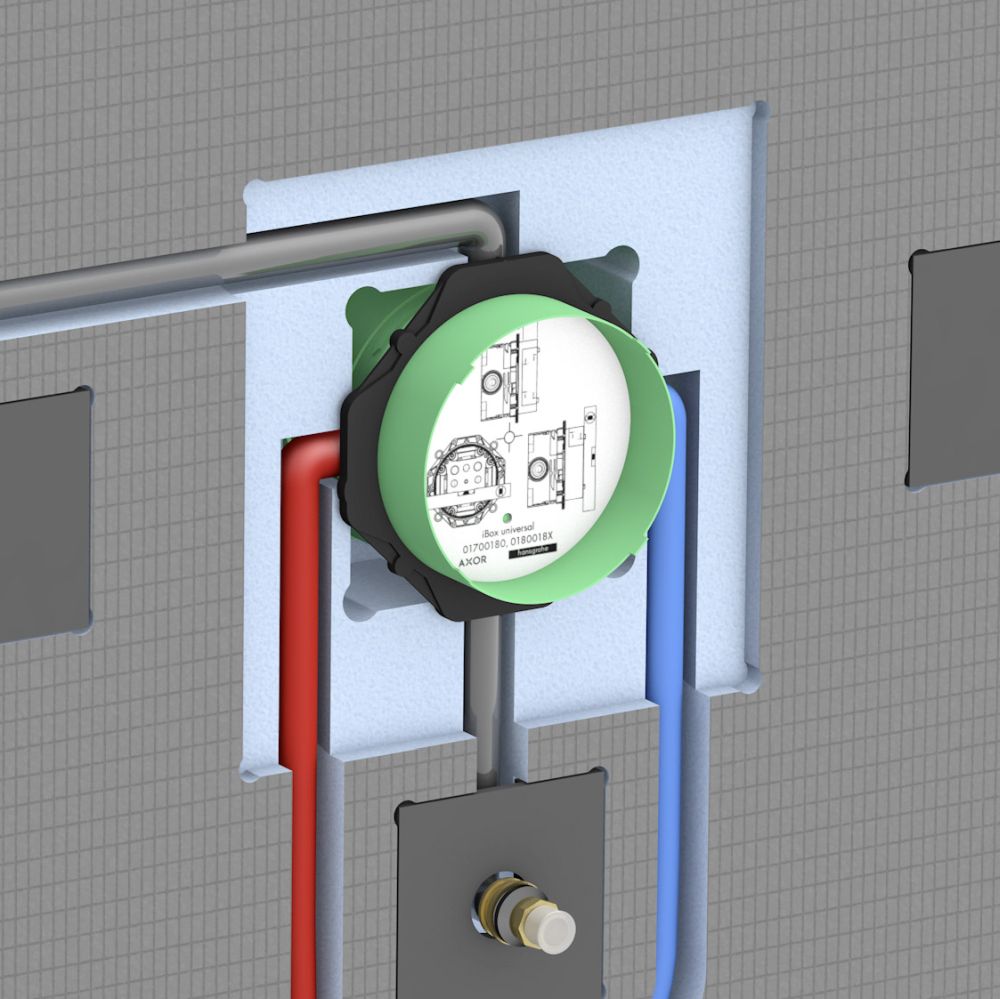

The main reason for saving time is that the wedi Sanwell shower wall module includes all pipes and connections when delivered to site. A Hansgrohe iBox, suitable for 200+ thermostatic mixer designs, is also included. The entire integrated technology is already sealed during manufacturing and so, no further waterproofing is needed. The wall therefore only needs to be fixed in place and connected to existing water pipes on the construction site. "Setting up and sealing of the iBox or the pipework is no longer necessary and assembly is much faster in comparison with traditional framework installations, whilst generating much less noise or dirt. What's more, the system is lightweight and can be easily installed by one person" explains Mr Hinze.

The shower wall module is suitable for use as a fixed wall or as a free-standing partition. There are many individualisation options too: to meet customer specific needs, the wall is available in different thicknesses and widths, the height of factory-integrated engineering components can be selected and even an integrated niche can be included upon request. Like all wedi building boards, the shower wall module is also 100% waterproof, has a blue core made of HCFC-free, extruded polystyrene rigid foam and its cementitious surface coat is an ideal basis for all types of tile and design surfaces.

wedi Sanwell shower wall module at a glance

- Prefabricated shower wall module with factory-integrated and sealed technology including a Hansgrohe iBox

- Included technical components can be placed individually at the appropriate height (head shower, iBox and holder for hand shower to suit left or right-handed users)

- Can be installed on almost any surface as a fixed wall or use as a free-standing shower partition wall

- Safe and straightforward installation thanks to the degree of prefabrication and low weight

- Short curing times, can be directly tiled as early as 12 hours after installation