wedi 320

„Tile adhesive can be used everywhere.“

Product information

Product features

wedi 320 high-quality tile adhesive is characterised by its stability under load and coverage, its creamy consistency, ease of use and long open time. The quality of wedi 320 is documented by the tested product properties C2 TE in accordance with DIN EN 12004.

Technical properties

| Technical properties of wedi 320 | |

| Mixing ratio | approx. 7.5 litres of water to 25 kg of powder |

| Processing time | approx. 5 hours |

| Tile application time (open time) | approx. 20 – 30 minutes (depending on absorbency and temperature) |

| Realignment time | up to approx. 15 minutes |

| Hard enough to walk on / grout | after approx. 24 hours |

| Suitable for underfloor heating | yes |

| Processing (air) temperature | min. +5 °C, max. +30 °C |

| Thickness of adhesive bed | up to max. 5 mm |

| Consumption | |

| 4 x 4 grooves: approx. 1.3 kg/m² 6 x 6 grooves: approx. 2.2 kg/m² 8 x 8 grooves: approx. 2.8 kg/m² |

|

| Packing | |

| 25 kg paper sack |

Areas of use wedi 320

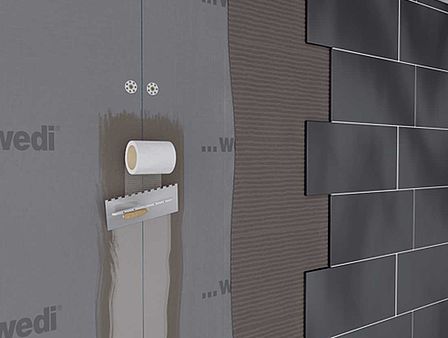

wedi 320 is a hydraulic binding agent-based, highly polymermodified quick-drying thin-bed mortar in accordance with DIN 18157 for full surface setting and laying of wedi building boards, wedi Fundo and wedi Subliner. In addition, it can be used for the bonding of tiles, glass mosaics and split tiles as well as natural and artificial stone slabs. The flexible adhesive can also be used on plasters made from cement, lime or gypsum, screed, concrete and prefabricated concrete elements (at least 3 months old), gypsum fibre boards, aerated concrete, mastic asphalt and insulating boards as well as the wedi sealing system.

In addition, wedi 320 is suitable for bonding of stoneware tiles, tile on tiles and for the laying of ceramic tiles and slabs on screeds with underfloor heating and anhydrite floating screeds etc. (The requirements in the “Ceramic tiling and slabs, natural and artificial stone on heated floor constructions” data sheet, 2007 edition, must be fulfilled.)