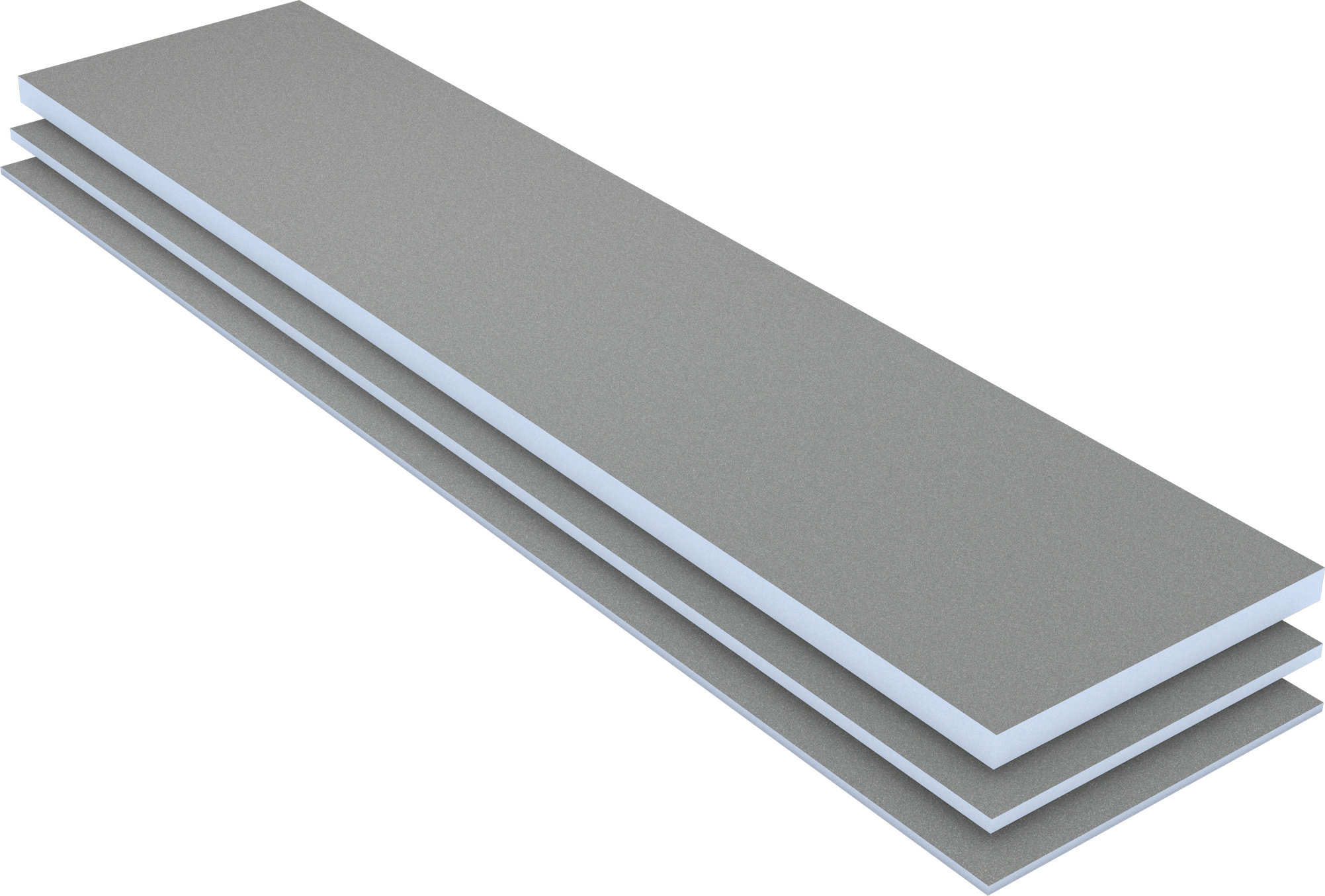

Building board Vapor

„The special building board for rooms with high humidity.“

Product information

wedi building board Vapor is a composite element made from extruded polystyrene rigid foam which is reinforced on both sides with a special cement coating, with a vapour barrier on one side.

- For rooms where there is a permanently raised level of humidity

- For walls, ceilings and floors

- Vapour barrier and thermal insulation

All advantages at a single glance

Product information

wedi building board Vapor is a composite element made from extruded polystyrene rigid foam which is reinforced on both sides with a special cement coating, with a vapour barrier on one side.

- For rooms where there is a permanently raised level of humidity

- For walls, ceilings and floors

- Vapour barrier and thermal insulation

Technical data of building board Vapor

| Dimensions | 600 x 2500 mm |

| Thickness | 14 mm, 21,5 mm, 51,5 mm |

| Vapour barrier (sanded epoxy-resin vapour barrier) | 1,5 mm |

| Diffusion equivalent air layer thickness, sd value (epoxy resin vapour barrier) | 283 m |

| Resistance to water vapour diffusion(µ) | EN 12086 188571 |

| Fire behaviour EN 13501 | E |

|

|

| Long-term compressive strength (50 years) ≤ 2% compression EN 1606 | 0,08 N/mm2 |

| Compressive resistance or compressive strength at 10% compression EN 826 | 0,25 N/mm2 |

| Associated modulus of elasticity EN 826 | 10 – 18 N/mm2 |

| Thermal conductivity EN 13164 | 0,036 W/mK |

| Tensile strength EN 1607 | 0,45 N/mm2 |

| Shearing resistance EN 12090 | 0,2 N/mm2 |

| Shear modulus EN 12090 | 7 N/mm2 |

| Bulk density EN 1602 | 32 kg/m3 |

| Resistance to water vapour diffusion(μ) EN 12086 | 100 |

| Water absorption under long-term immersion EN 12087 | ≤ 1,5 Vol.-% |

| Capillar action | 0 |

| Linear coefficient of thermal expansion | 0,07 mm/mK |

| Temperature limits | -50°C / +75°C |

| Fire behaviour EN 13501 | E |

| Propellant gas, carbon dioxide, GWP value | 1 |

Product sizes

Construction panels for rooms with high humidity: wedi building board Vapor

- The wedi building board Vapor may be used as heat insulation, while at same time, because of the coating applied in the factory; as a vapour barrier in rooms with permanently high humidity.

- Particularlwhen used for wall areas it is one of the best carrier elements on the market - especially when used for public shower and spa facilities. It is also suitable for tile and plaster carrier element.